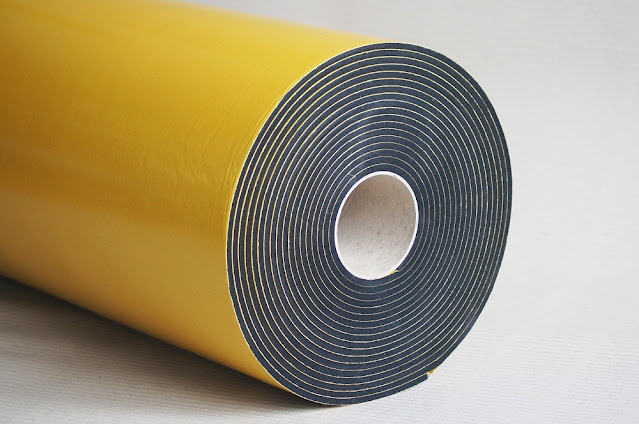

A self-adhesive rubber combines a material and an adhesive film used to bond or join objects instead of using fasteners, screws, or welding. Using adhesive tapes instead of mechanical fasteners, you can use lower temperature applications, simplifying manufacturing processes.

In addition, adhesive tapes protect your surfaces since they do not require fasteners or screws to attach. Tape adhesives are great to have some easy usages, while liquid adhesives require spraying or rolling on the surface before bonding.

Electrical self-adhesive rubber is employed in various applications to create a physical separation between circuits and users or surrounding components. Electrical components, such as cables and circuit boards, can be insulated from electricity.

This self-adhesive rubber tape prevents hazardous connections while limiting overvoltage in critical applications by isolating circuits.

|

| Self-Adhesive Rubber |

Know About Different Types Of Adhesive Tapes

Different types of electrical insulation tape are available based on the type of construction material, each with its own set of benefits and properties. Following are some common kinds.

- Vinyl Tape

Vinyl tapes are constructed from vinyl films and coated with rubber adhesives due to their exceptional weather and UV resistance.

The tape is available in many different colors, and it can be removed easily without leaving behind any heavy adhesive residue.

- Thermoplastic Insulation Tape

Flame-resistant and heat-resistant, transformer insulation tape can withstand extreme temperatures. Thanks to its excellent adhesive properties, you can create a tight coil construction using this tape.

Typical applications for transformer insulation tape include:

- Insulation with lead

- Wrapping and banding coils

- Transformers with and without oil

The Ultimate Benefits Of Using Self-Adhesive Rubber

- Reduces chances of injury

When working with electric components, self-adhesive electrical rubber dramatically enhances safety. When electrical insulation tapes are correctly used, there is a significant reduction in the risks of injury, death, and fire.

As well as preventing damage, data errors, and diminished performance, proper taping can also help prevent overvoltage issues in equipment.

- Stability

Electrical self-adhesive rubber strips are solid and hard to break if wrapped around two or more objects several times. In addition, it is resistant to acids. It will last for a long time before it loses its elasticity and needs to be replaced.

While electrical tape is strong, most can be torn off the roll by hand, with some permanent stretching around the break. It is, therefore, preferable to use a knife or scissors to cut it.

- Cost-effective

Well, when you want tapes in a large amount, going for the self-adhesive rubber is much greater option because it is highly cost-effective. You can get them in a lower budget which you cannot in case of silicon or acrylic based adhesive products.

- Controls Humidity

The self-adhesive rubber tapes work very efficient even if the environment is very much humid. It happens because of its hydrophobic nature.

- Soft material

As the base of these tapes are rubber, they are really soft in nature. therefore, whenever, you are using the rubber in any textured surface, it gets comfortable easily than the acrylic, or silicon tapes.

- Efficient

Rubber based adhesives are much more efficient than the silicon or acrylic tapes. It is efficient in sticking the substances together than other type of tapes. It adheres to a wide range of varieties. Therefore, in terms of serving the purpose, it is much more efficient.

Wrapping It Up:

There are many types of adhesive tapes and self-adhesive rubber tapes are the efficient and cost-effective ones. These are reliable and safe and provide proper security when attached to any wire or object. You can buy premium quality self-adhesive tapes for your needs.

Comments

Post a Comment